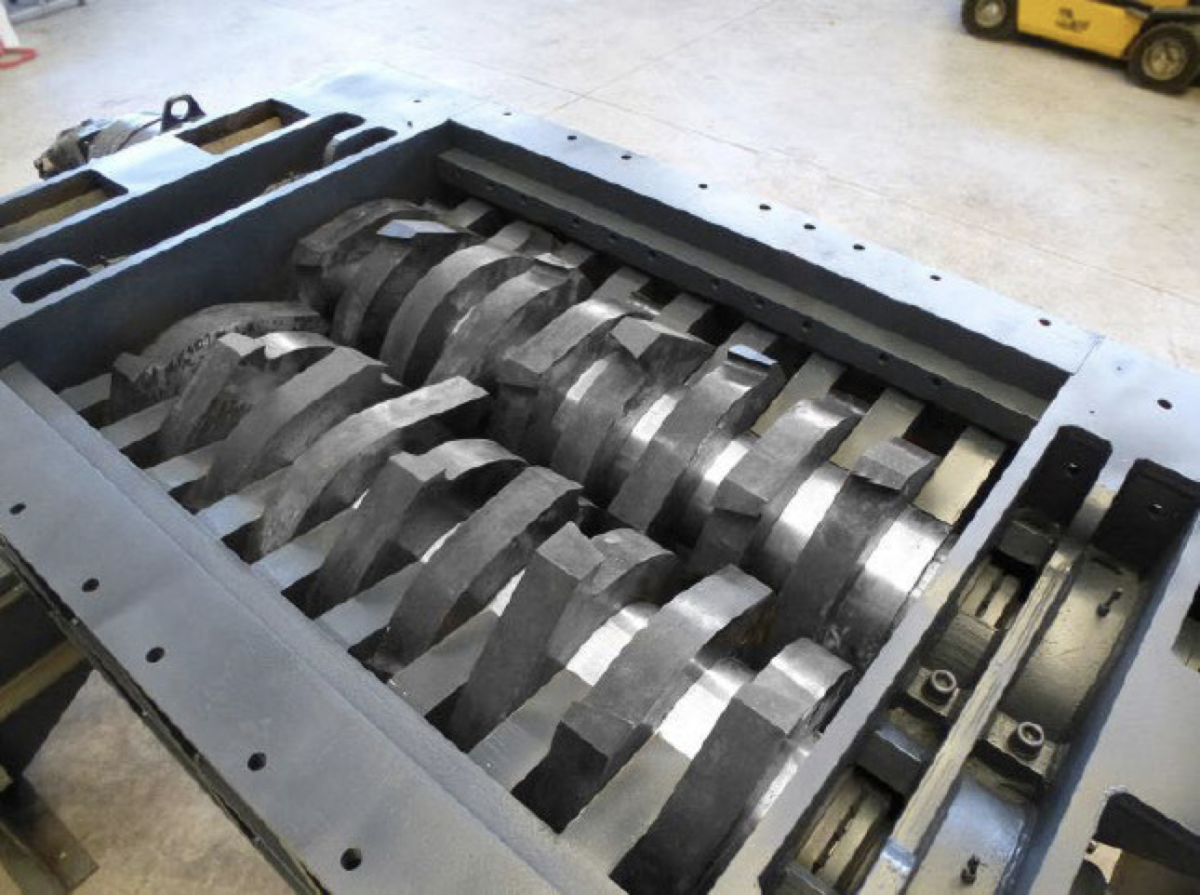

Medical waste shredder is a very important part in medical waste treatment. It is used for shredding all kinds of medical waste containing very hard materials like stainless steel surgical instruments, glass and hard ceramics, also soft materials such as gauze, protective suits.

Advantages:

- We have single shaft shredder, double shaft shredder, four shaft shredder.

- Power from 1.5kw~90kw which can meet different requirements.

- It can be equipped with dumper or conveyor which can save the labor and improve working efficiency

- With four-layer sealing structure and sealing is reliable

- The blade pressing plate adopts assemble structure, which is easy to disassemble

- It has anti-blocking function to prevent the blades to get jammed

- Fully automatic, easy to operate and maintain

- Advanced design of discharging system to avoid waste falling and order spreading

Please tell us the following information, we will quickly recommend to you:

- Processing capacity, per hour or per day.

- The name of the material to be crushed

- Size after crushing

- Description

-

Medical waste shredder is a very important part in medical waste treatment. It is used for shredding all kinds of medical waste containing very hard materials like stainless steel surgical instruments, glass and hard ceramics, also soft materials such as gauze, protective suits.

Advantages:

- We have single shaft shredder, double shaft shredder, four shaft shredder.

- Power from 1.5kw~90kw which can meet different requirements.

- It can be equipped with dumper or conveyor which can save the labor and improve working efficiency

- With four-layer sealing structure and sealing is reliable

- The blade pressing plate adopts assemble structure, which is easy to disassemble

- It has anti-blocking function to prevent the blades to get jammed

- Fully automatic, easy to operate and maintain

- Advanced design of discharging system to avoid waste falling and order spreading

Please tell us the following information, we will quickly recommend to you:

- Processing capacity, per hour or per day.

- The name of the material to be crushed

- Size after crushing