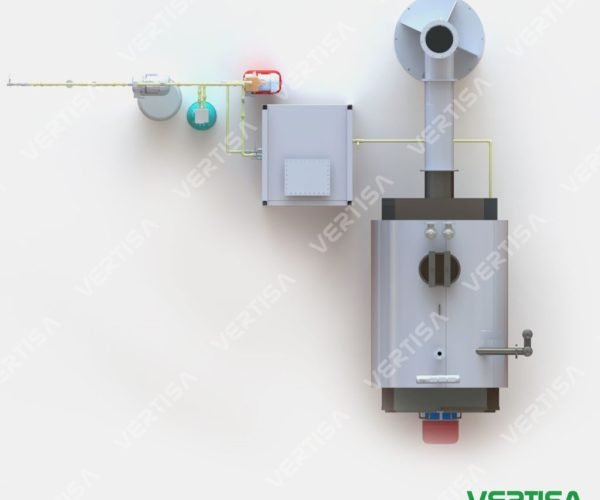

Our STATE OF THE ART highly efficient, fully cylindrical 3 PASS Scotch-type boilers have large water volumes in order to meet sudden steam injections. Vertisa’s steam boilers are highly preferred in the steam production industry due to their ease of maintenance and high effiency.

All design and manufacturing is in accordance with CE and DIN EN norms.