Our hinged door steam sterilizer is mainly used in operating room, central sterile supply department, third-party sterilization supply center and etc. to complete sterilization for surgical instruments, fabrics, rubber, bowls, implantable devices and others that can bear high temperature sterilization.

Features:

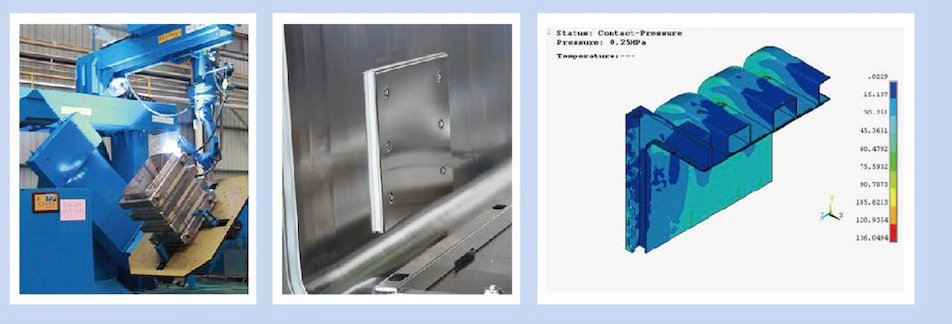

- Superb chamber machining and welding process. The acid-proof stainless steel chamber and jacket are automatically welded by robot.

- Steam baffle plates are surrounded by silicon rubber to protect the chamber surface and avoid steam spraying on the items directly.

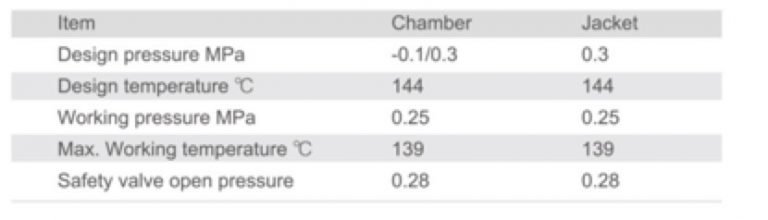

- Vertical sliding door. The door is vertical sliding via motor and chains which save the labor and avoid operator touching the door. It also save the installation space.

- Colorful touch screen on loading side, indicating lamps on the unloading side which is showing sterilization stage, time, temperature, alarm and other parameters in real time.

- Most of pipes, valves and components are designed and installed in one side, which is more convenient for maintenance.

- Compact designed sealing groove, durable circular hollow silicon gasket and sealed by compressed air.

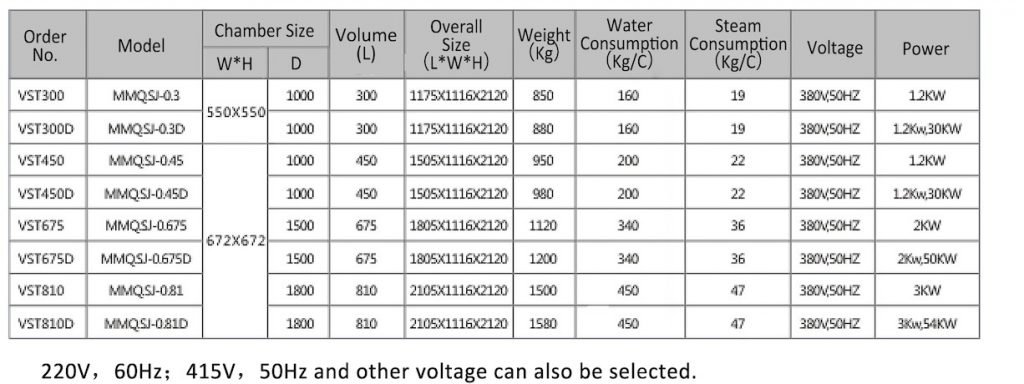

- Reliable and durable chamber. Chamber is designed according to professional analytical method. High-emulation software ANSYS is used for chamber simulation. Design service life: 10 years(or 20000times sterilization cycles)

- Description

-

Our hinged door steam sterilizer is mainly used in operating room, central sterile supply department, third-party sterilization supply center and etc. to complete sterilization for surgical instruments, fabrics, rubber, bowls, implantable devices and others that can bear high temperature sterilization.

Features:

- Superb chamber machining and welding process. The acid-proof stainless steel chamber and jacket are automatically welded by robot.

- Steam baffle plates are surrounded by silicon rubber to protect the chamber surface and avoid steam spraying on the items directly.

- Vertical sliding door. The door is vertical sliding via motor and chains which save the labor and avoid operator touching the door. It also save the installation space.

- Colorful touch screen on loading side, indicating lamps on the unloading side which is showing sterilization stage, time, temperature, alarm and other parameters in real time.

- Most of pipes, valves and components are designed and installed in one side, which is more convenient for maintenance.

- Compact designed sealing groove, durable circular hollow silicon gasket and sealed by compressed air.

- Reliable and durable chamber. Chamber is designed according to professional analytical method. High-emulation software ANSYS is used for chamber simulation. Design service life: 10 years(or 20000times sterilization cycles)

- Technical Specification

-