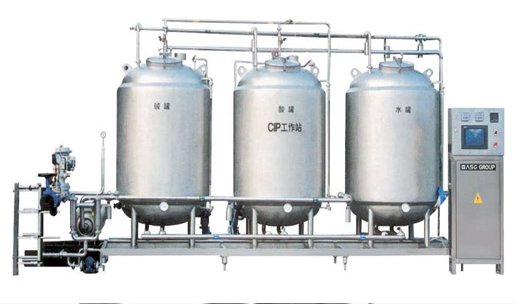

Pure water equipment requirements:

Water quality meets the provisions of GMP, FDA and USP.

The equipment works automatically and contains back flush, regenetration, acid-washing and disinfection process.

Monomer and pipes meet GMP requirements. The back-end disposal equipment, such as sterilizer, membrane filtration, terminal water tank and pipeline adopt 316L stainless steel and pre-treatment pipes adopt SUS304 stainless steel.