What’s pure steam?

Firstly, let’s see the difference between industrial steam, clean steam and pure steam.

- Industrial steam/ plant steam: The raw water is softened water. The steam is produced by conventional steel boiler. This steam is sterile but no clean because a lot of products and components coming from steam distribution system may contaminate the produced steam. The long distance transport may reduce the steam dryness. That’s the reason why industrial steam cannot be in direct contact with medical and pharmaceutical products. The industrial steam is only kept for indirect use or thermal supply.

- Clean steam/ process steam: The raw water is demineralized or osmosed water. The steam is produced by a stainless steel boiler. In addition, any water supply or steam distribution system should be made of stainless steel.

- Pure steam: The raw water is double osmosed water. The steam is produced by polished boiler which is made of 316L stainless steel. Stainless steel piping, fittings, and components are also made of 316L stainless steel. It have two heating modes. One is electrical heating and the other one is industrial steam heating.

Why pure steam?

Steam quality is defined as the measurable physical aspects of steam used for sterilization. Bad steam quality may lead to the following issues:

- Wet loads

- Damaged loads

- Unsterile loads

- Sterilization(biological and chemical) indicator failures

- Staining and corrosion og instruments and chamber

Pure steam has good performance in the temperature(superheat), dryness(liquid water content), and non0condensable gas content. So it can avoid above issues.

Why us?

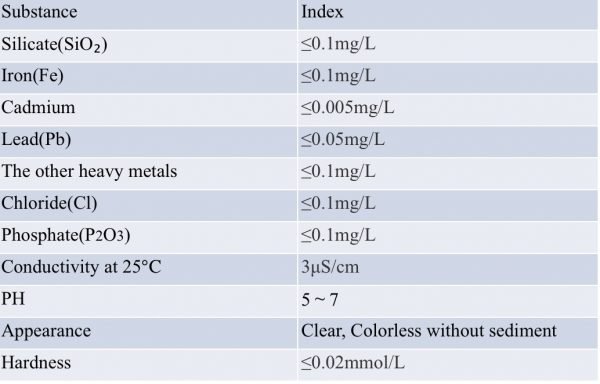

- Our design and production meets European standard EN285 sterilization. please check the following chart.

- We are the expert in the pure steam generator and can manufacture it according to customer’s needs. we have two heating modes: electrical heating and industrial steam heating.

- On the basis of meeting the requirements of EN285 standard, we can provide suitable reverse osmosis purifier to save customer’s needs to avoid waste.

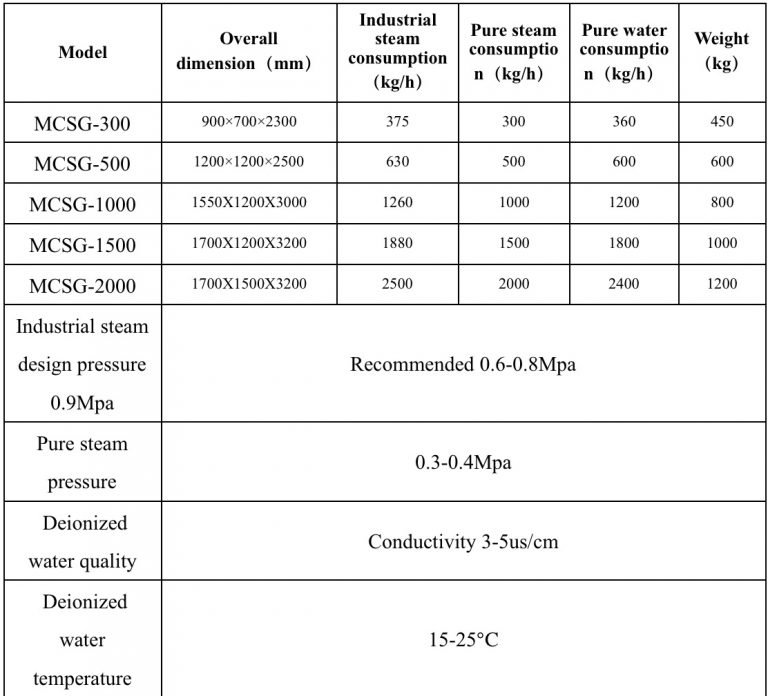

If you need more information, please check the technical specification.

Our PSG model pure steam generator is efficient, energy-saving steam generator. The steam quality complies with EN285 pure steam quality requirements. It is composed of distillation tower, preheater, soft drinks separation, control systems and other major components. Main components are made of 316L stainless steel. Control system is Siemens to ensure the stable operation of equipment. It has automatic and manual control modes. If automatic control system failed, operator can switch to the manual control.

Features:

- Distillation tower adopts advanced shell and time heat exchanger which can ensure the highest heating efficiency.

- The steam trap adopts the internal spiral three-stage separation technology to effectively remove the water droplets in the steam, and the dryness is maintained above 0.95, which meets the requirements of EU EN285.

- Boiler and pipes are made of 316L stainless steel which guarantee the clean environment

- Industrial steam pipeline, pure steam pipeline, pure water pipeline have pressure monitoring.

- Siemens control system

- The insulation material is made of 55mm thick aluminum silicate fiber, and the outer surface temperature is less than 35 ℃.

- Description

-

What’s pure steam?

Firstly, let’s see the difference between industrial steam, clean steam and pure steam.

- Industrial steam/ plant steam: The raw water is softened water. The steam is produced by conventional steel boiler. This steam is sterile but no clean because a lot of products and components coming from steam distribution system may contaminate the produced steam. The long distance transport may reduce the steam dryness. That’s the reason why industrial steam cannot be in direct contact with medical and pharmaceutical products. The industrial steam is only kept for indirect use or thermal supply.

- Clean steam/ process steam: The raw water is demineralized or osmosed water. The steam is produced by a stainless steel boiler. In addition, any water supply or steam distribution system should be made of stainless steel.

- Pure steam: The raw water is double osmosed water. The steam is produced by polished boiler which is made of 316L stainless steel. Stainless steel piping, fittings, and components are also made of 316L stainless steel. It have two heating modes. One is electrical heating and the other one is industrial steam heating.

Why pure steam?

Steam quality is defined as the measurable physical aspects of steam used for sterilization. Bad steam quality may lead to the following issues:

- Wet loads

- Damaged loads

- Unsterile loads

- Sterilization(biological and chemical) indicator failures

- Staining and corrosion og instruments and chamber

Pure steam has good performance in the temperature(superheat), dryness(liquid water content), and non0condensable gas content. So it can avoid above issues.

Why us?

- Our design and production meets European standard EN285 sterilization. please check the following chart.

- We are the expert in the pure steam generator and can manufacture it according to customer’s needs. we have two heating modes: electrical heating and industrial steam heating.

- On the basis of meeting the requirements of EN285 standard, we can provide suitable reverse osmosis purifier to save customer’s needs to avoid waste.

If you need more information, please check the technical specification.

- Technical Specification

-

Our PSG model pure steam generator is efficient, energy-saving steam generator. The steam quality complies with EN285 pure steam quality requirements. It is composed of distillation tower, preheater, soft drinks separation, control systems and other major components. Main components are made of 316L stainless steel. Control system is Siemens to ensure the stable operation of equipment. It has automatic and manual control modes. If automatic control system failed, operator can switch to the manual control.

Features:

- Distillation tower adopts advanced shell and time heat exchanger which can ensure the highest heating efficiency.

- The steam trap adopts the internal spiral three-stage separation technology to effectively remove the water droplets in the steam, and the dryness is maintained above 0.95, which meets the requirements of EU EN285.

- Boiler and pipes are made of 316L stainless steel which guarantee the clean environment

- Industrial steam pipeline, pure steam pipeline, pure water pipeline have pressure monitoring.

- Siemens control system

- The insulation material is made of 55mm thick aluminum silicate fiber, and the outer surface temperature is less than 35 ℃.